Methanol, widely seen as a viable fuel for large-scale adoption, can help significantly reduce CO2 emissions in shipping. In the MENENS project, 21 partners, including RH Marine, are creating a framework for using methanol as a safe, cost-effective, sustainable fuel.

What makes methanol a particularly interesting alternative is its density, relatively high yield, reasonable production cost, limited flammability, and sustainable production methods, using biomass for example.

The project

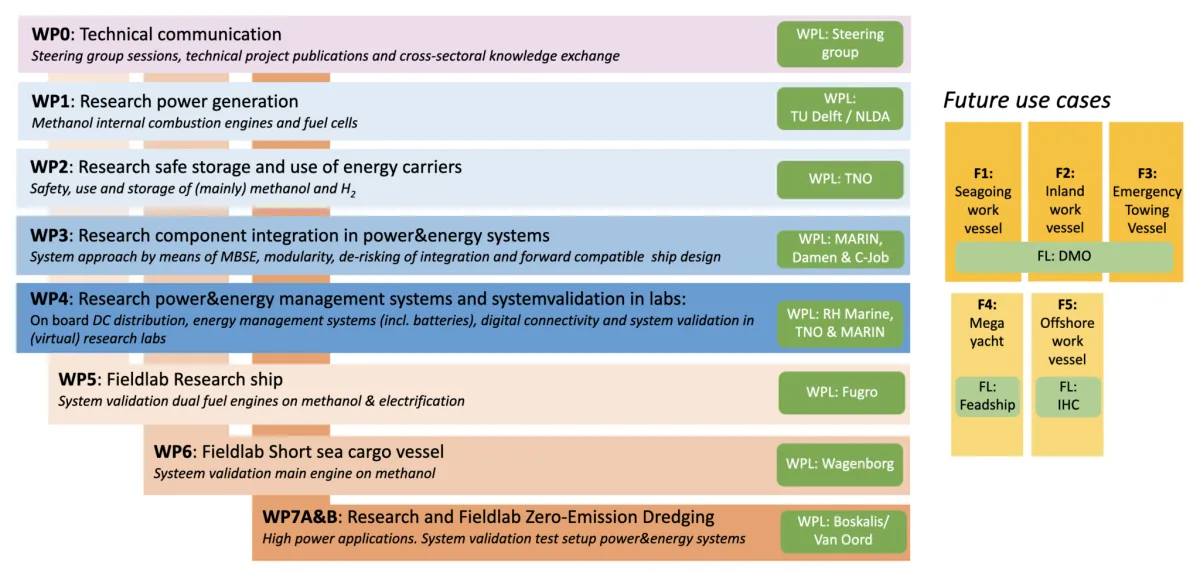

“The MENENS project consists of seven work packages related to transitioning to methanol-propelled ships, each with a different focus,” explains Despoina Mitropoulou, Manager Power Systems. “We are participating in and coordinating MENENS Power and Energy systems research and development. We’re in the lead of work package four, focused on realisation of grid design and energy systems, including topics such as simulation, digital twinning, IoT and, connectivity. A fair part of the work is related to coordinating the different lines of research. We make sure to connect with work packages related to ours and facilitate sharing of information and technology. Quite a challenge, due to the level of detail involved in each work package. Work package three, for example, is focused on Model-Based System Engineering, which the marine industry is increasingly adopting. Other packages look at making diesel engines suitable for methanol, performance testing, and safety aspects, including analysing risks and introducing mitigation measures.”

Key challenges related to sustainable power sources are their dynamic behaviour and integrating them into a grid design. RH Marine Power Systems department is investigating ways of making such systems more stable by integrating storage systems and thus maximizing their performance. The team is also investigating methodologies that allow us to see the impact of certain steps and interdependencies between elements when designing a system. This helps to make the systems modular and see the implications of certain changes across a system. Nobody can predict the future, but this approach makes it possible to design-in flexibility and keep platforms as modular as possible.

Project roadmap

Overcoming challenges

“One of the main challenges when it comes to realising zero emission shipping is the fact that nothing can compete with diesel right now. Ship owners find it tough to switch to alternative fuels that don’t match diesel’s range and energy density. Methanol, for example, needs more space onboard due to its lower energy yield compared to diesel. Also, adopting methanol requires new ideas for infrastructure, maintenance, and storage.

“Technical challenges include DC grid design, reducing weight and increasing efficiency. Energy sources such as fuel cells and batteries, which are inherently DC, are becoming more prominent. Introducing DC on the secondary side, where people might connect devices such as laptops, can bring more efficiency, but also introduce technical complexity. Another main challenge is the system integration of a grid design which also touches on aspects such as cooling, which needs to be implemented in different ways if a distributed power solution is chosen. What’s more, there are many standards and regulations for AC, but not for DC. Each potential use case needs to be examined and discussed separately with classification agencies and standards bodies.”

In the past, Despoina has worked on projects in which information was shared with knowledge institutes. The MENENS project is very different, however, as knowledge is shared with competitors! “We’ve found a good flow and structure, and everybody seems quite happy. We have regular meetings to share results based on selected topics, assign tasks, and agree on specific actions and common deliverables. Everything is carefully documented by all parties. It’s impressive to see how much people are sharing. There’s a great deal of mutual trust and openness.

Developing smart solutions

“Combining combustion engines with fuel cells and using smart software and intelligence to manage and optimise fuel consumption are key to our work,” says Despoina. “Vessels’ sailing profiles play an important role in this. Some vessels, such as ferries, show very predictable patterns, whereas those of yachts, for example, are much more variable. In 2015, we were already working on a hybrid yacht and developing an energy management system which used a fuel consumption optimisation algorithm to decide when to use diesel power, and when to use power from batteries. This considers factors such as the lifecycle of the batteries and charging efficiency losses. We’re now applying this approach to methanol, which introduces different degradation behaviours across scenarios.”

Control strategy

The systems being developed by RH Marine Power Systems team can be validated by simulating a wide range of conditions. The idea is to make the control strategy as robust as possible by introducing variables, based on a vast range of factors that can be encountered at sea, and checking whether systems are sufficiently adaptable. That requires a lot of modelling and simulation. The team is using digital twins, as well as an extensive component library, developed with TNO and Marin, which can be reused for projects of different sizes, power ratings, and applications. This library of easily configurable models can be shared with partners, helping them test anything from yachts to dredgers.

Thinking differently

When striving to reduce energy usage and emissions, fuel consumption is a good place to start. However, there are other improvement possibilities. Ships are currently designed with a maximum speed in mind, for example, but why size them in that way if that maximum speed is never actually required? Do ships really need to carry two weeks’ supply of diesel if they’re never away from a port for more than a few days?

Fieldlabs and real-life testing are key to the MENENS project. For example, one partner is converting a ship from their existing fleet to use methanol. They’re replacing two out of four engines and comparing performance to ‘regular engines’ in live tests. Another fieldlab is testing dredging vessels, introducing different load profiles. Fieldlabs are sharing data based on engine testing and performance, which is further enriched by results from knowledge institutes. Solutions and proposals are all modelled, simulated, and pretested, ensuring they’re compliant with the relevant legislation and standards and fully operational once they reach the real world.

Despoina adds: “We’re sharing requirements with fieldlabs and requesting specific data which we feed into our models, validating assumptions, simulations, and the models themselves. Different types of input from different sources also help us understand how innovations can be applied in different regions. With Bakker Sliedrecht, we’re developing a DC lab where we can test and simulate fuel cells, batteries, and methanol engines to find out more about their behaviour. The DC lab can accommodate different sustainable sources, as well as components from partners. We can even reconfigure complete designs on the fly. The idea is to accelerate introduction and uptake of new designs.”

“We need to determine where we can make trade-offs between benefits and integration challenges while optimising operational cost and without compromising on safety aspects. Available data related to methanol is very limited right now, so we’re implementing a highly flexible optimisation strategy, that can accommodate many different sources and models. We can find correlation between many different factors, from type and level of emissions to noise or vibrations.”

“RH Marine is already very focused on sustainable and zero emission shipping, participating in discussions to influence the industry. The Maritime Masterplan was fully aligned with our own goals, especially related to on-board zero-emission sources. With the MENENS project, there was also a high level of strategic alignment with what we were doing around the development of efficient power and energy systems. Once the resulting innovations are implemented in the market, industry processes and supply chains will change for the better and best practices can be copied and introduced worldwide.”